|

Intake Manifold Porting & Polishing by Ned Erkman |

|

|

Intake Manifold Porting & Polishing by Ned Erkman |

|

|

The intake manifold is very important for developing efficient engine performance as this important engine airflow component directly affects the amount of air and fuel that is distributed into each cylinder in an internal combustion engine, which directly affects the power production capability of the engine. The purpose of the intake manifold is to provide intake airflow to the cylinder head which makes the intake airflow capacity of the cylinder head only as good as the airflow supplied by the intake manifold. The intake manifold is quite often more restrictive than the cylinder head which means that significant power and performance can be obtained from intake manifold porting but since intake manifolds do not have technical flow data information published as cylinder heads do and since complete CNC porting and polishing is not usually available for intake manifolds these airflow components are often ignored since they are not very well understood in terms of importance for power production. The only effective option available to evaluate the intake manifold airflow efficiency is by performing flow tests on a flow bench. Then the best way to modify an intake manifold for better flow is by performing labour intensive hand porting and polishing modifications that are also flow tested and evaluated on a flow bench. Developing high quality porting modifications for an intake manifold is a complex process that requires extensive knowledge of science, physics, aerodynamics and fluid dynamics along with the successful experience needed to deliver superior engine performance results. Superior performance results like this 440 Chrysler engine with original production block and original 3.75 inch stroke crankshaft producing over 670 Rear Wheel Horsepower on our Mustang Chassis dyno, with our extensively ported Edelbrock four barrel intake Manifold. This excellent engine power is a great example of how high quality intake manifold and cylinder head porting and a high tech custom camshaft can produce big power in a production block with a stock crankshaft. The fact is that high quality intake manifold and cylinder head porting can deliver amazing power which is clearly demonstrated with this 1970 Chrysler 440 engine, which was originally rated at 375 horsepower, now producing over 770 Horsepower. It is important to comprehend that this 440 engine produces more than double the 375 HP the stock engine block and crankshaft originally produced, which is proof positive of how good porting modifications deliver great performance results.

|

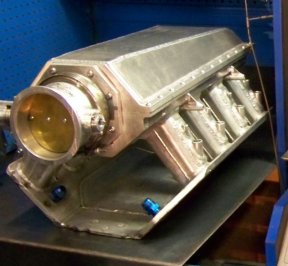

Porting 440 Intake Manifold |

Flow Testing 440 Intake |

440 Chrysler Engine |

9.43 @ 143 |

|

Edelbrock 440 Intake Manifold being ported and flow tested then installed on a 440 Engine equipped with extensively ported Brodix B1 BS Heads. This Chrysler 446 CID engine uses a 1970 production block and stock 440 crankshaft with a .030 Forged Piston to produce over 770 Horsepower. Intake Manifold and Cylinder Head Porting Modifications by Don McQuag & Ned Erkman, custom solid roller camshaft designed by Ned Erkman.

Intake Manifold Basic FunctionTechnically, the airflow that enters an engine passes through a carburetor or throttle body that is installed on the intake manifold and the function of the intake manifold is to direct this incoming airflow into the cylinders in the engine by moving the air towards the intake ports in the cylinder head through intake manifold passage ways that are called the "intake manifold plenum" and the "intake manifold ports". The incoming airflow first enters the intake plenum, which is an enclosed space inside the intake manifold that distributes air flow into the intake manifold ports. The intake manifold ports direct the airflow into each cylinder in the engine by moving airflow into the intake port in the cylinder head. This means that the airflow that enters an engine through a carburetor or throttle body moves through the intake manifold plenum and then into the intake manifold ports towards the intake ports in the cylinder head and it is quantity and quality of flow that enters the cylinder head that affects engine power. The flow capability of the intake manifold passage ways directly determines the power produced in each cylinder of the engine and improving intake manifold airflow through the process of intake manifold porting is very beneficial for increasing engine power and improving engine acceleration.

Intake Manifold DesignThe design and shape of an intake manifold has a major affect on engine airflow and the amount of air that flows into each cylinder in the engine is directly affected by the intake manifold. The intake manifold can restrict intake airflow to the intake port of the cylinder head by a range of 2% to 30% which entirely depends on the flow efficiency of the intake manifold. It is also important to understand that the distribution of intake airflow into each cylinder is not always equal as the different shapes, sizes, lengths and locations of the intake manifold plenum and ports have an affect on how air flows into each cylinder in the engine. Intake manifolds have been developed to work with different size engines and for different rpm operating ranges so it is important to select the best manifold to use for a specific engine application.

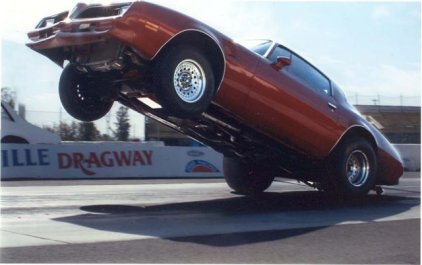

Intake Manifold Airflow DistributionIt is extremely important to understand that many tuning problems and the cause of much engine damage is directly related to different air/fuel ratios and spark tuning variation problems that occur in different cylinders do to intake manifold distribution problems. This variation of intake airflow into each cylinder creates an imbalance in engine performance as each cylinder produces a different level of power in the engine which tuners attempt to fix with different air fuel mixtures and spark timing adjustments for each cylinder. The root problem with the production of different levels of power in each cylinder is actually hardware problem that can not be properly fixed by high tech tuning software. The application of a different fuel and spark tune into each cylinder does not address the imbalance of power in each cylinder which is caused by an intake manifold airflow distribution problem. This unequal balance of airflow into each cylinder also creates an unbalanced engine where each cylinder generates a different level of power and this unbalanced engine power affects the acceleration rate of the engine, since the cylinders that have a lower level of power cause a drag on the engine that prevents the engine rpm from increasing at a smoother and faster rate of speed. This is a weak link scenario where cylinders that make less power from not getting enough intake airflow slow down the engine acceleration rate. Porting Modifications to increase airflow in ports that flow less air will make more power and deliver great engine acceleration. The porting modifications to this intake manifold and our custom cylinder head porting modifications along with our custom valve-train components resulted in a 6 MPH increase in performance and 5 tenths of a second increase in drag strip quarter mile performance with the same 383 CID small block engine and hydraulic roller that originally powered this 1968 Camaro. ET performance improved from 11.80's to 11.30's while MPH increased from 114 to 120 MPH.

|

|

|

|

|

|

Intake Manifold and Cylinder Head Flow Bench PortingIntake Manifold flow restrictions and variations in intake airflow into each cylinder can only be properly adjusted and improved through porting modifications that are tested and tuned by the use of a flow bench. Since there are no CNC programs that are designed to completely port and polish intake manifolds the process to conduct "intake manifold porting" is extremely limited since very few people have the expertise to affectively modify intake manifolds and cylinder heads as a system to get equal distribution into all the cylinders in an engine. This makes custom intake manifold flow bench porting a very limited and exceptionally valuable service for high performance racing engines. In cases where a significant variation in engine power is diagnosed between cylinders it is important to understand that to balance the power production in each cylinder, to being near an equal level of power, intake manifold porting modifications and cylinder head porting modifications need to be performed through flow bench testing to balance the intake flow into each cylinder as a system. The total flow through the cylinder head with the intake manifold attached is what determines the total flow to each cylinder and flow testing the cylinder head with the intake manifold attached, as a system, is what needs to be tested and evaluated on a flow bench. It is the total flow through the intake manifold and cylinder head intake port that must be balanced for equal or near equal power production to occur in all cylinders inside the engine and the successful results of this modification process can provide dramatic engine acceleration rates and unparalleled engine performance. |

Ford Small Block Intake |

814 CID BBC Intake Manifold |

Ford 302 Boss Intake Manifold |

Ferrari Intake Manifolds Stock and Ported |

|

Carburator and Fuel Injected ManifoldsThe function of an intake manifold is different in a carbureted engine and a fuel injected engine since a carbureted intake manifold is required to move air and fuel through the intake manifold whereas a fuel injected engine is only required to move air. The significance of this is that air is lighter than fuel and is able to move easier around turns, whereas fuel is denser and heavier requiring a bigger turn radius in the intake manifold to properly flow from the carburetor into the cylinder head. This is why carburetor manifolds have large turn radiuses in the intake ports, whereas EFI manifolds have straight runners that go directly to the cylinder head.

Dual Plane Carburator Intake ManifoldsCarburetor intake manifolds were originally developed as dual plane intake manifolds with each cylinder having a completely different length intake manifold port and shape which limited the flow capability and RPM range of these manifolds. Modifications and improvements in design have enhanced the performance capability of dual plane intake manifolds to have better distribution between cylinders with higher engine RPM capabilities that are now capable of operating at a range of 6500 plus RPM. This original 1968 to 1969 Big Block Chevy Intake Manifold for a high performance 375 hp 396 engine and 425 horsepower 427 CID engine makes more efficient power with our extensive custom intake manifold porting modifications. The images below, are before and after of the same two ports. |

BBC Dual Plane Intake GM# 3933163 |

Stock Intake Ports |

Ported Intake Ports |

|

|

|

|

Pro Street Champion Ricky Carlos inspecting his original 1969 Big Block Intake Manifold that is ported and flowbench tested to flow over 324 CFM through his original 1969 cast iron cylinder heads that are also ported to flow more than many new aluminum heads and intake manifolds. The ported classic intake manifold and cast iron heads will be going down the drag strip this year in his daily driver pump gas powered 1969 Camaro.

|

|

Single Plane Carburator Intake ManifoldsSingle plane carburetor intake manifolds were developed for high performance only applications do to the higher RPM operating ranges which usually start in the 3000 plus RPM range up to 8000 RPM. Single Plane intake manifolds are used on most serious high performance street engines and almost all racing engines where they are not prohibited by racing rules. Single plane manifolds offer a significant improvement in power and performance over dual plane intake manifolds at higher operating ranges above 6000 RPM.

Fuel Injection ManifoldsElectronic Fuel Injection manifolds have a completely different design than carburetor manifolds since fuel flow is not built into the design. Fuel injected intake manifolds have intake manifold port designs that go directly straight into the cylinder head intake port which improves both air flow and fuel flow do to the straight entry of airflow into the cylinder head. The straight intake runner EFI intake manifold designs are only possible since these intake manifolds do not have to flow fuel which is denser and heavier than air and requires a larger turn radius from the plenum. EFI manifolds can have a 90 degree turn from the plenum where air is able to make this sharp turn and fuel is unable.

|

Chrysler 6.1 Hemi Intake |

Corvette LS7 Intake |

Dodge Viper V10 Intake |

|

Fuel Injection Polymer ManifoldsThere are modern fuel injected engines that use high tech polymer materials to produce more power by reducing the heat absorbed into the airflow that enters the engine. Reducing the air temperatures by 10 degrees Fahrenheit can produce 1% more power do to the cooler and denser air that flows through a polymer/plastic material. These new plastic intake manifolds are also lighter than aluminum intake manifolds so this new technology offers the advantage of more power production from cooler air intake temperatures and less weight which also helps vehicle performance. Porting modifications are also beneficial for these new plastic manifolds to improve flow and make more power. This is why aftermarket polymer intake manifold manufacturers such as FAST produce intake manifolds that can be disassembled to make it easier to modify these manifolds by porting. |

|

|

|

|

Centrifugal & Turbo ManifoldsForced inducted engines require intake manifold runners that go directly straight into the cylinder head since a straight airflow entry is less disruptive to fuel flow. The flow of fuel is most important to forced inducted engines and airflow that enters straight into the engine that delivers smoother less turbulent air flow produces more efficient power and is less likely to cause engine damage. Carburetor manifolds can be modified for forced induction but air that is under pressure wants to go straight and when forced inducted air is require to turn in a carburetor manifold the pressurized air flows on the outside wall of the intake port runner , do to boost pressure, which can push the fuel that is entering the intake port from the fuel injector towards the other side of the intake runner. This can cause turbulent fuel flow that does not have good mixture velocity. Improper fuel flow that does not flow with the airflow can cause fuel to make contact with the cylinder wall which can stick to the cylinder wall until the piston ring comes up and scrapes the fuel off the cylinder wall. This is the primary reason for lifting rings and blowing up pistons as is clearly evident by how this phenomenon always happens right beside the intake valve where the fuel flow enters the cylinder. Intake manifold designs and modifications that promote good fuel flow are best for all engines and especially for forced inducted engines that flow a lot more fuel. |

Extensively Modified Manifold |

Straight Intake Manifold Ports |

2 fuel rails & 24 fuel injectors |

|

Intake Manifold Porting Modification ServicesAfter reviewing the content of our "Intake Manifold Porting" presentation we hope that there is a clear awareness that we fully understand the significance of the intake manifold and how important this engine airflow equipment is to the overall performance of a high performance engine. This is why we specialize in designing and developing some of the highest technology intake manifold modifications with an established record of delivering superior engine performance. We also specialize in providing intake manifold and cylinder head flow testing services that help to evaluate the efficiency of customers new or used intake manifolds and cylinder heads to better determine what performance modification services are best suited for the intended engine application. Our intake manifold & cylinder head matched combination porting and polishing services are conducted to work as a system to improve overall airflow efficiency through both the intake manifold and cylinder head in order to deliver very significant improvements in engine power and acceleration. Technically, intake manifold porting modifications that increase airflow by 1 CFM (Cubic Feet per Minute) when the intake manifold is installed on the cylinder head can produce 2 horsepower in a V8 engine and flow bench porting modifications that equalize and balance the rate of airflow from the intake manifold to all the cylinders in the engine can improve the acceleration rate of the engine. We have a proven record of developing intake manifold and cylinder head systems that have increased total flow by over 60 CFM which amounts to power improvements that have the potential to exceed 120 Horsepower for naturally aspirated engines. Our extensive knowledge and successful experiences in the modification of high performance intake manifolds has a verified history of delivering superior performance results.

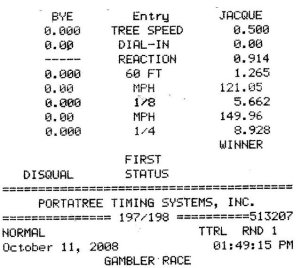

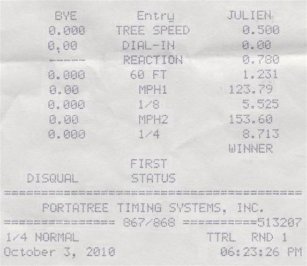

The small block Chevy intake manifold that we developed flowed a lot more air than a high dollar ($2000) big brand name intake manifold that we flow tested and compared to our manifold modifications. Our custom single four barrel intake manifold porting modifications along with our custom cylinder head modifications and our custom designed solid roller camshaft improved the performance of the naturally aspirated small block Chevy engine that powers this Firebird by more than half a second (0.5 second) in the quarter mile. |

Testing another brand intake |

Flow testing our ported intake |

Flow testing our modifications |

Our Porting & Cam ET & MPH ET 8.92 sec at 149.96 mph |

Vehicle weight is over 3200 lb. Small Block Chevy engine with Brodix heads |

Chassis work & better traction ET 8.71 seconds at 153.6 MPH |

| Single 4 barrel Intake Manifold Porting prices start at $400 |

| Dual Plane Intake Manifold porting prices start at $300 | Polymer Intake Manifold Porting prices start at $200 |

| Throttle Body Porting Prices start at $200 |